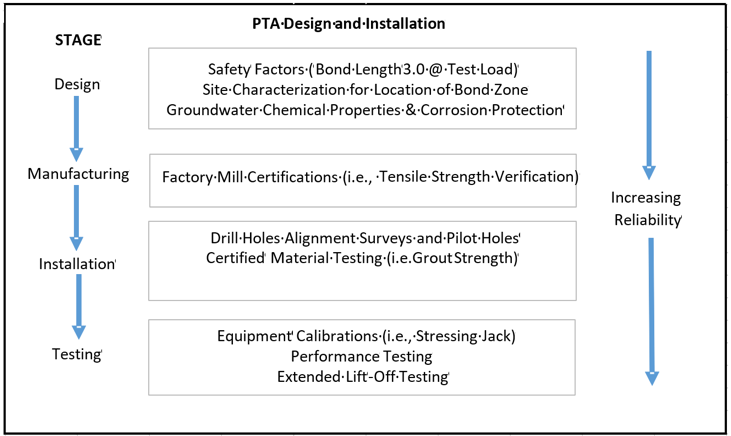

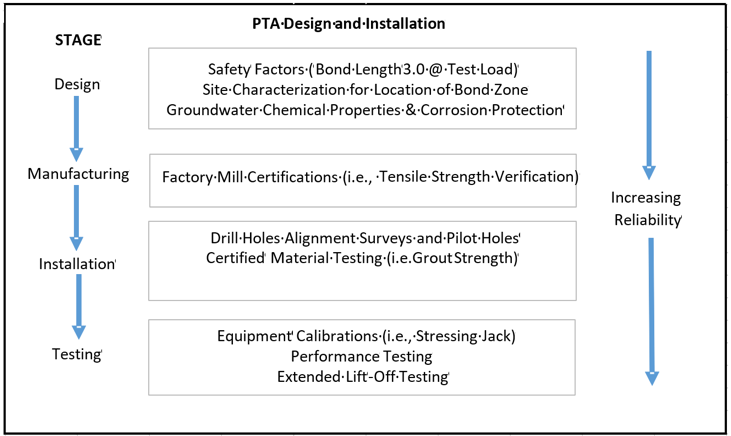

Design and installation practices provide high reliability in PTA systems. Features of these practices include:

- Design

- High factors-of-safety in required bond length.

- Site investigations are carried out in order to characterize a site; particularly the bond zone.

- Additionally, the ground-water at the site must be analyzed to determine its chemical properties. The analytical results reveal the potential corrosive power of the groundwater so that mitigation steps may be taken.

- Manufacturing

Factory mill certifications are required to ensure wire strengths are achieved

|

- Installation

- Pilot holes are drilled before boring the entire cavity for the PTA tendon. The alignment and location are confirmed through this test, and then the final holes are drilled.

- Material strengths are tested on site to ensure the materials meet design requirements (e.g. the grout). Also, the strands are tensioned to 80% of the guaranteed ultimate tensile strength (GUTS).

- Testing

- The test equipment is calibrated prior to use.

- Lift-off tests are performed to confirm the tension in the tendons and the strength of the tendons themselves.

|