- PTA Front Page

- Concept

- Design

- Corrosion Protection

- Resources

- Search the Post-Tensioned Anchor Database

Corrosion protection is an important component for providing reliable life-time service of post-tensioned anchors systems. There are a number of types of corrosion that prestressed steel may experience:

- general corrosion

- localized corrosion

- stress corrosion/hydrogen embrittlement

- fatigue corrosion

- stray current corrosion

- bacterial attack

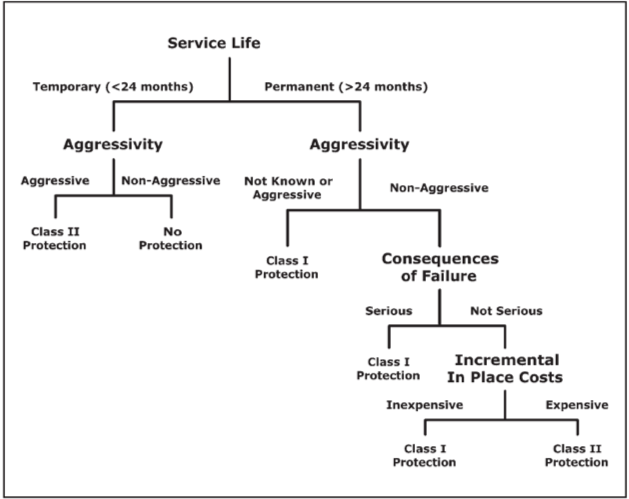

The last 3 types on this list generally apply to special circumstances (FHWA, 1999). Corrosion protection may include one or more physical barrier layers which protect the tendon from a corrosive environment. The barrier layers include anchorage covers, corrosion inhibiting compounds, sheaths, encapsulations, epoxy coatings, and grouts. The selection of the physical barrier depends on the design life of the structure (i.e., temporary or permanent), aggressivity of the ground environment, the consequences of failure of the anchored system, and the additional cost of providing a higher level of protection.

The Post-Tension Institute (PTI) provides guidelines, including a decision tree for post-tension anchor design and corrosion protection (see the figure to the right) (PTI, 2014). There are two levels of protection that are recommended – Class I and Class II. Considerations in the decision tree include longevity of the anchors (temporary or permanent), chemical aggressivity of the water and rock environment, consequences of an anchor failure and incremental cost of Class I versus II protection.

As described by PTI (2014),

- Class I Protection - A Class I Protection system encases the prestressing steel inside a plastic encapsulation filled with either grout or corrosion inhibiting compound. An epoxy-coated strand tendon grouted into a drill hole that successfully passes the water pressure test.

- Class II Protection - A Class II Protection system encases the prestressing steel over the free length and relies on the cement grout to protect the prestressing steel along the bond length. Epoxy coating on bar tendons provides additional protection and enhances the Class II Protection but does not qualify as a Class I Protection.

The following table summarizes the corrosion protection requirements for Class I and II.

Encapsulated Tendon |

Trumpet Cover if exposed |

|

|

Grout Protected Tendon |

Trumpet Cover if exposed |

|

|

Citations

Federal Highway Administration, (1999). Ground Anchors and Anchored Systems, Geotechnical Engineering Circular No. 4, Publication No. FHWA-IF-99-015.

Post-Tension Anchor Institute (2014). Recommendations for Prestressed Rock and Soil Anchors, Phoenix, AZ.