- PTA Front Page

- Concept

- Design

- Corrosion Protection

- Resources

- Search the Post-Tensioned Anchor Database

Overview

|

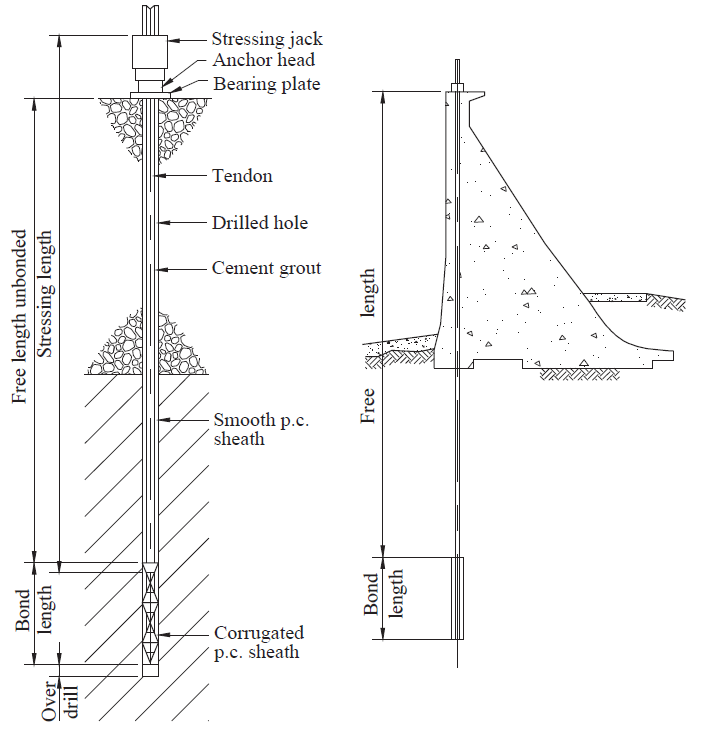

Post tension anchorage systems (PTA) are an efficient and effective means to improve the stability of dams. In North America PTA have been in use since the 1960’s; world-wide they have been used since the 1930s. PTA are used to secure the dam structure to bedrock through a series of steel strands imbedded in concrete and rock. Once installed, the steel is tensioned so the strands develop forces along their length, adding stability and strength to dams, making them safer and more long-lasting. As this technology has advanced, there are have been continued improvements in:

Advances in these areas have increased the reliability of PTA and provide greater assurance of long-term performance. |

Cavill BA. Very high capacity ground anchors used in strengthening concrete gravity dams. In: Littlejohn GS, editor. Ground anchorages and anchored structures, Proceedings of the International Conference, London. London: Thomas Telford; 1997. p. 262-271. |

Basic Terms

| Tendon: This term refers to the complete assembly: steel strands, anchorages, and ducts. Strand: Several steel wires wound around each other create a strand. Typically, a seven-wire strand made of high-strength steel is used and conforms to ASTM A416/A416M. The center wire around which six additional wires are wound is referred to as the king wire. Duct: Made of plastic or metal, the duct containing the steel strands which will be filled with grout to secure the steel in place. Transition tube or Trumpet: This conical duct feeds the steel strands into the main duct. Inlet/Outlet? Wedge: This piece holds the end of the strands in place, preventing them from being pulled into the duct once they are tensioned. Wedge plate: The wedges bear against the wedge plate, transferring the steel strand forces onto this plate and securing the system. Bearing plate: The wedge and bearing plates act together to disperse the force of the pre-stressed steel strands onto the exterior of the system. Confining steel: Present outside of the duct, the confining steel gets embedded in the surrounding concrete to reinforce the area around the tendon. Unbonded vs. Bonded Tendon Bonded: The pre-stressing steel is permanently fixed within the duct; it cannot move relatively to the concrete (or grout) around it. Unbonded: The pre-stressing steel is unconstrained within the duct; coated in grease, it is not bonded to the concrete so it can move relatively to the concrete. The pre-stressing forces get transferred to the concrete solely by the anchorages. |

|

|