Waterproofing Specialists and Contractors with Geomembranes

Construction

Each CARPI system is custom designed for the specific project. Procedures and materials are selected depending on the type of dam and upstream facing, on degree of deterioration of the upstream face, on severity of environmental conditions, on the possibility of seismic events, and on the desired seepage results.

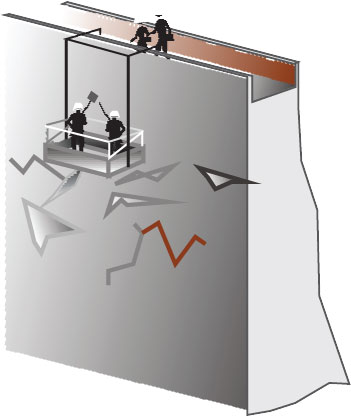

Installation Procedure for a Standard Intervention

1-2 Surface Preparation

The intervention begins with preparation of the surface of the upstream face to ensure sufficient subgrade exists to securely anchor and seal the profiles. Since the system can be installed on fairly rough surfaces, removal of all loose material and subsequent patching of the most severely damaged areas are usually sufficient. In the case of extremely rough surfaces, a thick geotextile can be installed against the dam face as an additional anti-puncturing and transition layer.

3 Installation of Vertical Anchorage Profiles

The intervention continues with installation of the internal vertical profiles on the face of the dam. Profile locations are determined during the system design to eliminate conflicts with construction joints or other features of the dam. The profiles are fastened to the dam face by expansion and/or chemical anchors.

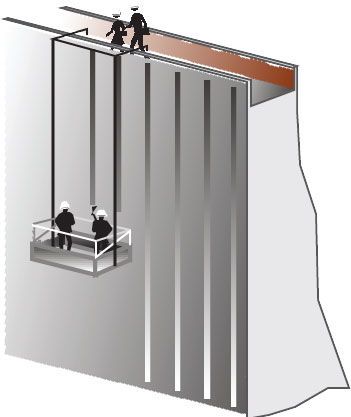

4 Installation of the Continuous Surface Drainage Layer

When a higher drainage capacity is required, an additional layer of geosynthetic material (geonet, geotextile or other synthetic material with high transmissive properties) is installed against the upstream face of the dam. The material is anchored to the dam by impact anchors placed at predetermined locations.

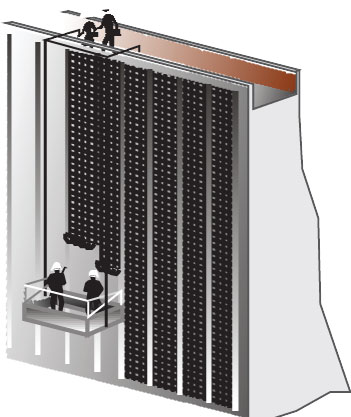

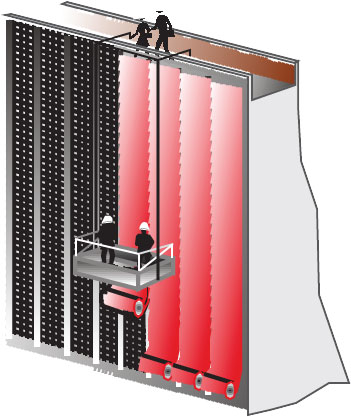

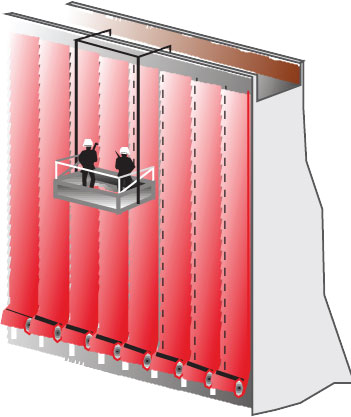

5-6 Installation and Anchorage of the Waterproofing Liner

The liner is supplied in rolls manufactured in a plant. Each roll is first anchored at the crest, then deployed and aligned, then anchored and pre-tensioned from both edges using the external vertical profiles. Tensioning smoothes the material and removes any wrinkles or sagging. The overlap of adjoining sheets is welded using hot air welders, followed by the installation of the perimeter profiles. Finally, the external vertical anchorage profiles are covered with geomembrane strips and hot air welded to the waterproofing liner.

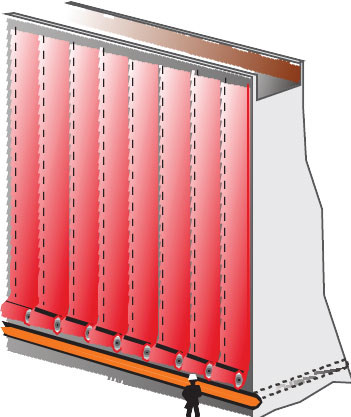

7 Drainage Collection and Discharge system

The drainage collection system is installed above the watertight perimeter anchorage at the heel of the dam, between the waterproofing geocomposite and the dam face. The system consists of a free-flowing collection pipe or drainage geonet connected to transverse conduits that discharge into the inspection gallery or at the downstream face of the dam. The system can be divided into sections to improve the accuracy of monitoring the source and quantity of infiltrating water. The system can be further enhanced with the addition of an optical fiber cable or electrical sensor system, which allows very precise monitoring of waterproofing efficiency.

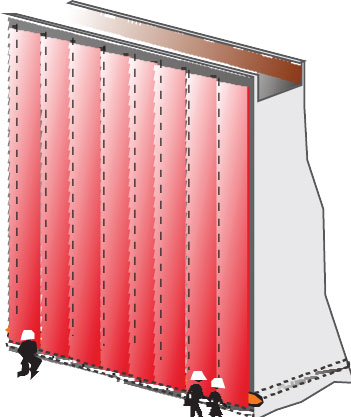

8 Installation of the Perimeter Anchorage Sealing Profiles

The installation of the watertight perimeter anchorage is one of the most critical aspects of the system. The greatest care is taken to ensure absolute watertight integrity especially at joints or fissured zones, where water could by-pass the system and infiltrate behind the liner. Expansion and/or chemical anchors secure the perimeter profiles, which in turn compresses the gasket material (for surface smoothing and for distribution of the compressive stress) and geocomposite against the dam face.